Add 2-3 LARGE CLOSEUP photos of spring coils in use

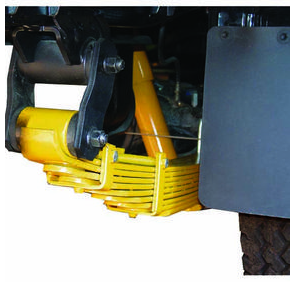

[/one_full]RSA offers improved-design, heavy-duty (up-rated) springs for African specs. The springs are manufactured from the highest quality BHP spring steel. The upgraded springs give increased height to the vehicle, proviing the necessary flexibility in the vehicle’s suspension to ride over uneven surfaces. The increase in spring rate is designed to avoid most cracks (in the body, frame, etc.) from handling, stability and load carrying.

RSA Off-Road Gas-Pressurized Shock Absorbers are matched to the needs of off-road vehicles with our specified Australian Springs suspension kit. This provides luxury comfort on normal roads, while always providing enough safety in the damper to ensure it will cope with a harder driving style on rough terrain. Its key elements are purposely designed working pistons that release high damping force at very low piston speeds.

Features:

- Performance

- Durability

- Safety

- Comfort

- Serviceable units

- Mono-tube design

- Longer service life.

The King Springs leaf spring promises good performance and durability. It is load-rate treated to ensure exacting quality control and accurately heat treated to ensure durability. In addition, individual leaf spring ends are diamond-cut to reduce inter-leaf friction and improve the distribution of pressure on the load-bearing surfaces between leaves. The spring is manufactured from high-grade spring steel to increase elasticity and memory, lengthen life and improve safety. Another safety feature is the military wrap, which keeps the spring in a drivable position if the main leaf breaks because of extra abuse. Anti-friction pads are placed between the leaf spring and the clip in order to reduce noise and friction. Similarly, nylon pads are positioned between leaves to reduce friction. Graphite coating also reduces friction between leaves for supple performance. For better rebound control, bolt clips are used instead of fold-over clips wherever possible. Importantly, the leaf spring is quality-assured: A strict quality program is adhered to throughout all stages of manufacturing.